[dropcap style=”font-size:100px; color:#992211;”]T[/dropcap]rebuchet three-point plan for collapse of Military-Industrial-Politico-Consumerist-Capitalist Superstructure:

Buy 3D Printer

Print 3D Printer

Take 3D Printer back to shop.

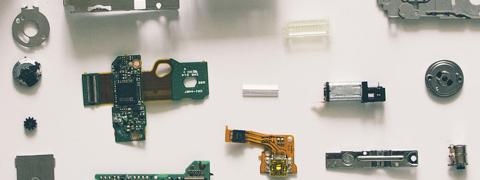

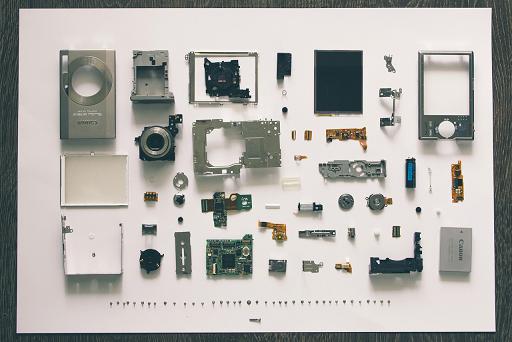

Various microstructures fabricated by a solvent-cast 3-D printing technique

Research work by the team of professors Daniel Therriault and Marie-Claude Heuzey makes the cover of the prestigious journal Small.

Polymers and Composites

Various microstructures including straight filaments, layer-by-layer scaffolds and freeform helical spirals are fabricated by a solvent-cast three-dimensional printing technique, as reported by Professor Therriault and his co-researchers on page 4118.

The fabrication capabilities of this powerful and flexible process are demonstrated by the printing of three microsystems featuring mechanical, microfluidic and electrical functionalities, such as a high-toughness microstructured fibre, a 3D microchannel and a Ka band antenna. These capabilities can be extended through the utilization of other thermoplastic-based inks and the printing of features at the submicrometer- and potentially nanoscale.

This is the first scientific publication by Shuang-Zhuang Guo, a doctoral student in mechanical engineering under the supervision of Professors Therriault of the Laboratory for Multiscale Mechanics (LM2) and Marie-Claude Heuzey of the Department of Chemical Engineering, both members of Polytechnique’s Montréal’s Centre for Applied Research on Polymers and Composites (CREPEC).

Source: Polytechnique Montréal

Photo: Vadim Sherbakov

Some of the news that we find inspiring, diverting, wrong or so very right.